Expanded Beam Insertion Loss Analysis

Steve Wilkes – QPC Fiber Optic, LLC

August 2019

Summary

The insertion loss in expanded beam connectors is a function of design and manufacturing process. Starting with an optimized design and high yield manufacturing process is mandatory, and final testing against master connectors is essential to verify optical performance. The details of QPC’s design, manufacturing process, and the typical loss results of expanded beam inserts are outlined below.

Design Considerations

QPC’s expanded beam connectors are designed around precision ARCAP AP1D connector inserts. This is a high tensile strength, chemical / corrosion resistant, thermally stable alloy. These inserts are the working part of the connectors and they hold up to four fused silica ball lenses, one for each fiber in the final assembly. The ball lenses expand the optical signal to up to 50x the fiber core diameter making the interface less susceptible to external misalignment and contamination issues. These lenses are permanently bonded to the ARCAP making for an environmentally sealed system. Spring loaded ceramic ferrules holding the optical fibers are inserted behind the lenses to make the optical connections.

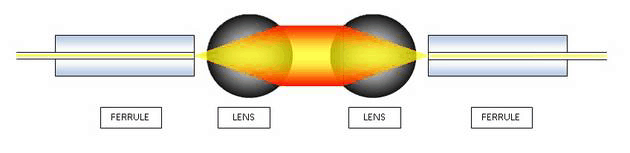

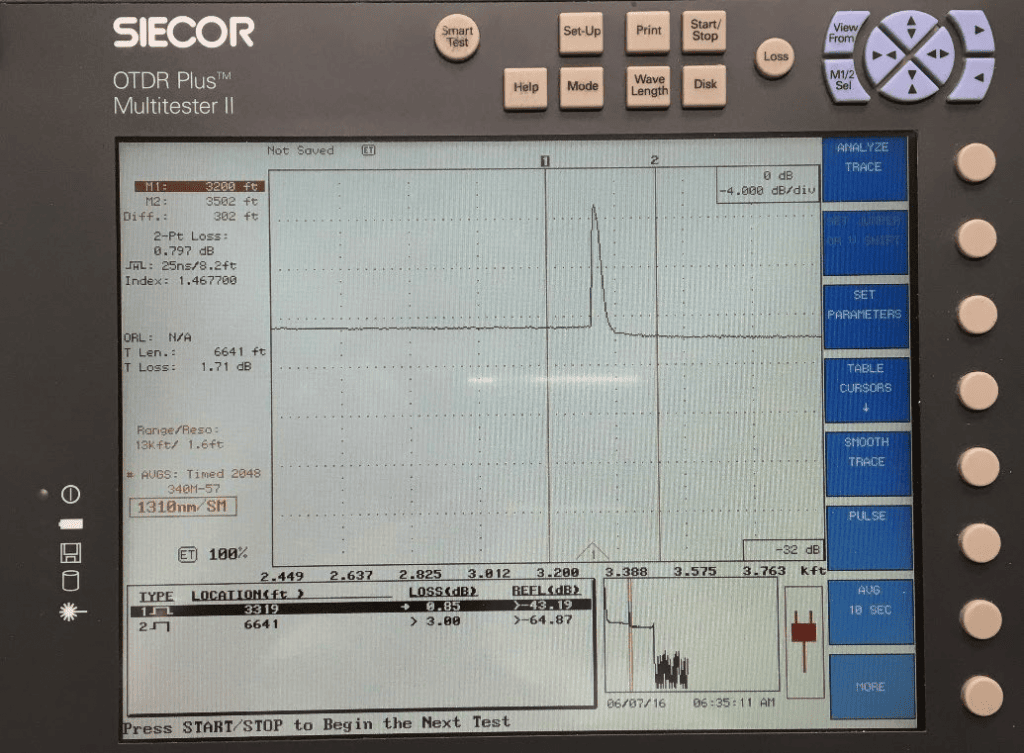

The optical path from fiber to fiber includes two fiber end faces, two ball lenses, and an air gap. The internal alignment, the component tolerance stack-up, the six optical surfaces, and the air gap, all contribute to the overall insertion loss (2.0dB max for Singlemode) which is significantly higher than that of a typical physical contact connector (0.25dB – 0.50dB). The diagram below shows the working elements for a single channel of an expanded beam connector.

To minimize insertion loss due to alignment and component tolerance stack-up, QPC specifies machining tolerances of < 1μm on key features of the inserts. The most sensitive aspect of the optical path is ferrule to ball lens alignment, X, Y & Z as well as angular misalignment. All are hypercritical due to the small core sizes of optical fibers, particularly the angles. Singlemode (SM) fibers have a core size of 9μm, and Multimode (MM) fibers have a core size of 50μm or 62.5μm. Aligning these cores to the free space optical path requires extremely tight tolerances on the inserts and a high level of precision in the lensing operation. QPC accomplishes this by using temperature-controlled machining and custom designed form tooling.

Another source of loss in these systems is the optical coupling loss due to the six reflective optical surfaces and the air gap. QPC’s design uses proprietary anti-reflective (AR) coatings to minimize this. The ball lenses are coated with two different types of coatings. One hemisphere is coated with a thin film structure that is optimized for glass-to-glass transfer – this is positioned where the fiber / ferrule couples to the ball lens inside the connector. The other hemisphere uses a coating designed for a glass-to-air interface – this is positioned where the ball lens is coupled to the mating ball lens with an air gap in between.

Manufacturing Process

QPC’s manufacturing process for the lensing the inserts is designed to produce high yields (> 98%) with predictable insertion losses (1.00dB ±0.50dB). This process is proprietary to QPC and involves precision lens alignment under a microscope as well as a permanent bonding process using UV cured epoxy. Each batch of inserts is serialized, so that loss data can be tracked throughout the process and provides for full traceability if needed.

In addition to the inserts, QPC’s fiber termination process is also designed to produce minimal insertion losses. QPC’s connectors are designed so that any experienced fiber optic cable assembly house can successfully assemble them. Because of the design elements described above, no assembler or end user tuning is required to achieve acceptable loss results. However, better than average insertion losses can be achieved if the fiber optic cable assembly process is automated.

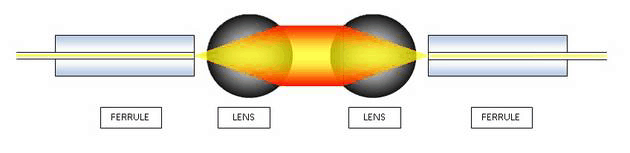

To accomplish this, QPC uses a Krell Sceptor Automated Polishing system for all of our cable assemblies. This unit is unique because its workholder features individual spring suspension for each connector / termini being polished. This ensures that each termini makes sufficient contact with the polishing film, regardless of ferrule height, and ensures extremely consistent end face geometry. QPC measures apex offset, end face radius, and fiber height against GR-326-CORE, IEC-60874 and Military standards to qualify our polishing processes using a FiBO Interferometer. The image below shows the polisher’s specialized workholder.

In practice, QPC has demonstrated that the combination of tightly controlled manufacturing on the inserts / connectors and automatically polished termini produces the best possible insertion losses on finished cable assemblies. Because the expanded beam connectors are designed to compensate for minor fiber assembly imperfections, QPC estimates that 85% of the variation in insertion loss can be attributed to the insert / connector and 15% to the assembly process.

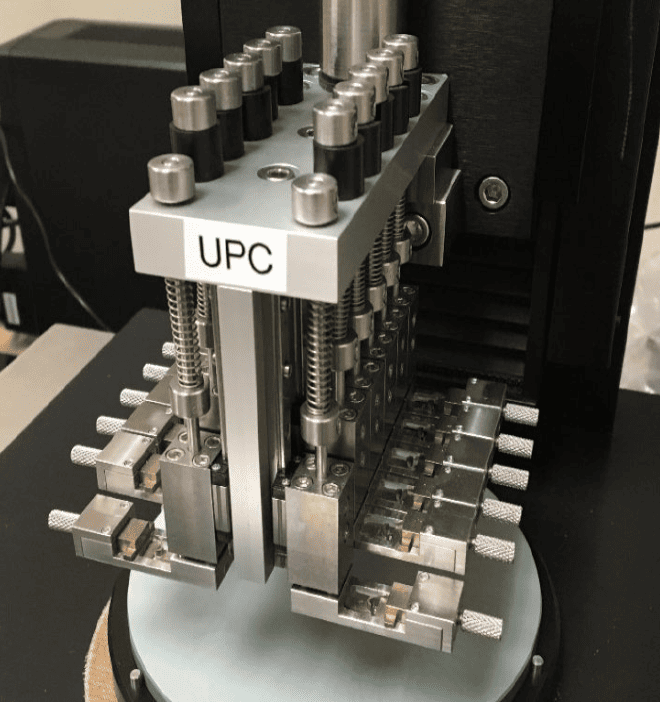

Testing

QPC’s test platform for expanded beam inserts is an Optical Time Domain Reflectometer (OTDR) equipped with both SM and MM test modules. We use long length access and trailing cables to completely isolate the expanded beam interface for an accurate measurement that is not affected by variations in test cables or reference techniques. Tests are run at 850nm & 1300nm for MM inserts and 1310nm & 1550nm for SM inserts. Due to the sensitivity of these components, 100% of assembled inserts (all channels) are tested and individual test data is recorded for each serialized part.

Each batch of manufactured inserts is tested against QPC’s Master Inserts. These Master Inserts were identified when QPC launched the product line several years ago. The Master Inserts were selected from a group of 10 inserts that exhibited better than average test performance. These 10 were then tested amongst themselves – each insert to every other insert. The four that performed the best (typical insertion losses < 0.75dB on all channels) were designated as Master Inserts. One pair is used routinely in testing and the other pair is reserved to re-qualify Master Inserts in the unlikely event that the ones used in testing are damaged. Every insert that QPC has produced since the release of the product line has been tested against these Master Inserts to ensure consistency. This is essential to be able to guarantee that all fielded connectors will be intermateable and backward compatible.

A typical OTDR test result is shown below:

Acceptance Criteria

QPC’s Expanded Beam products are designed to the specifications outlined in MIL-83526/20. This specification states that the average insertion loss for any individual channel (tested under multiple mates / de-mates) must be < 1.5dB for MM and < 2.0dB for SM and that the maximum insertion loss be < 2.0dB for MM and < 2.5dB for SM.

To ensure compliance with this requirement, QPC’s internal standard is to set the maximum insertion loss at 1.5dB for SM and MM. This provides a margin of error of 0.50dB (MM) to 1.0dB (SM) that is necessary to account for inherent discrepancies when mating with connectors produced by different manufacturers, as well as the fact that insertion loss will degrade slightly with time when connectors are exposed to “real world” conditions.

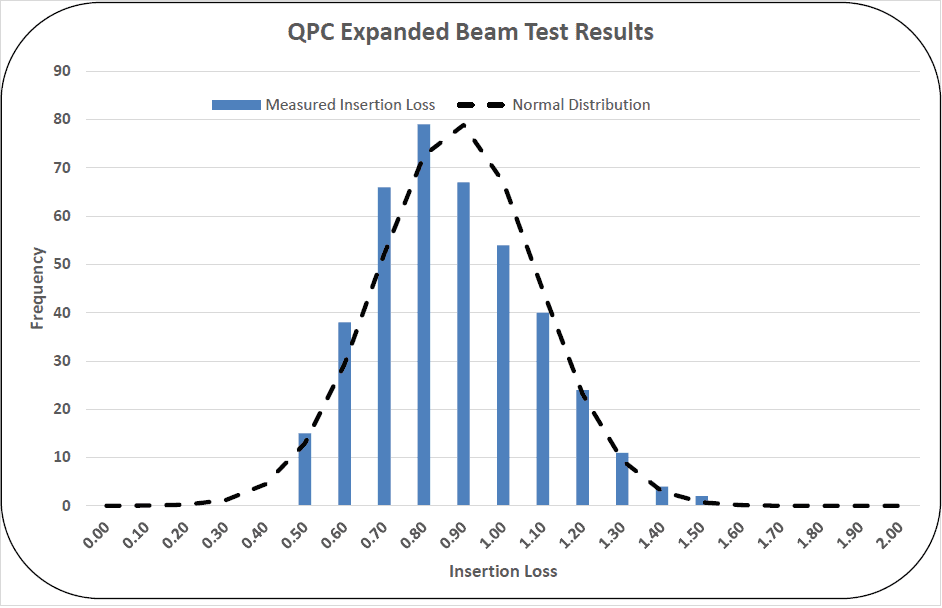

QPC’s product design and manufacturing process described above consistently yields > 98% of finished parts at or below this level. The optical performance level of a randomly selected channel, can be determined by statistical analysis. The chart below shows individual channel test results for 400 channels – 100 expanded beam inserts with 4 channels each. The values range from 0.5dB (Close to the theoretical limit) to 1.5dB (QPC’s Max) with a mean of 0.834dB and a standard deviation of 0.20. Comparing the actual data to a normal distribution curve shows a reasonably close correlation.

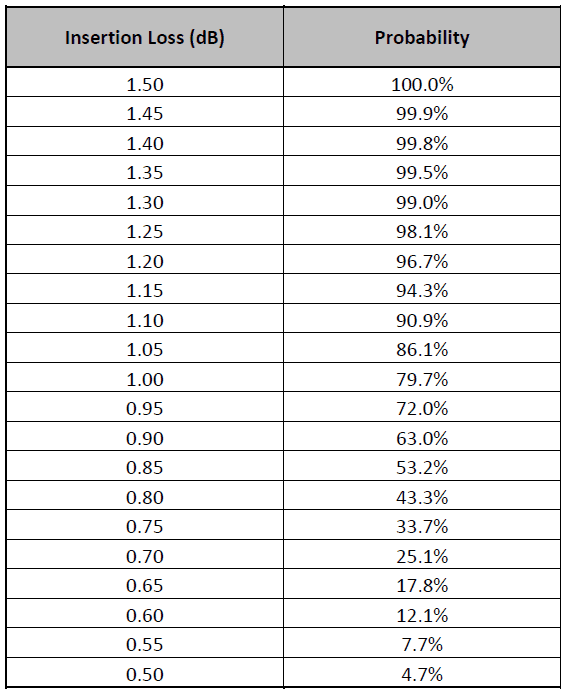

Since the distribution is normal, the probability of insertion loss for an individual channel being a specific value can easily be calculated. The following table shows the probability that an individual channel will perform at or below certain levels. When calculating these values, it is important to subtract the chance of a value being < 0.5dB (~2%), since this is not theoretically possible due to spherical aberrations, and the chance of a value being > 1.5dB (~3%), since these are scrapped.

Conclusion

As shown with the data above, careful attention to the design and manufacturing process for Expanded Beam connectors can produce components that perform well under the maximum attenuation levels generally accepted by the end user community. Approximately 80% of QPC’s SM Expanded Beam connectors read at or below 1.0dB, and 98% are at or below 1.25dB. This allows designers to confidently manage their system loss budgets to ensure that outputs are well within the dynamic range of the optical receivers.

Check out QPC’s product page for our QMini, QMicro, and QPlex Expanded Beam Connectors https://www.qpcfiber.com/products/.